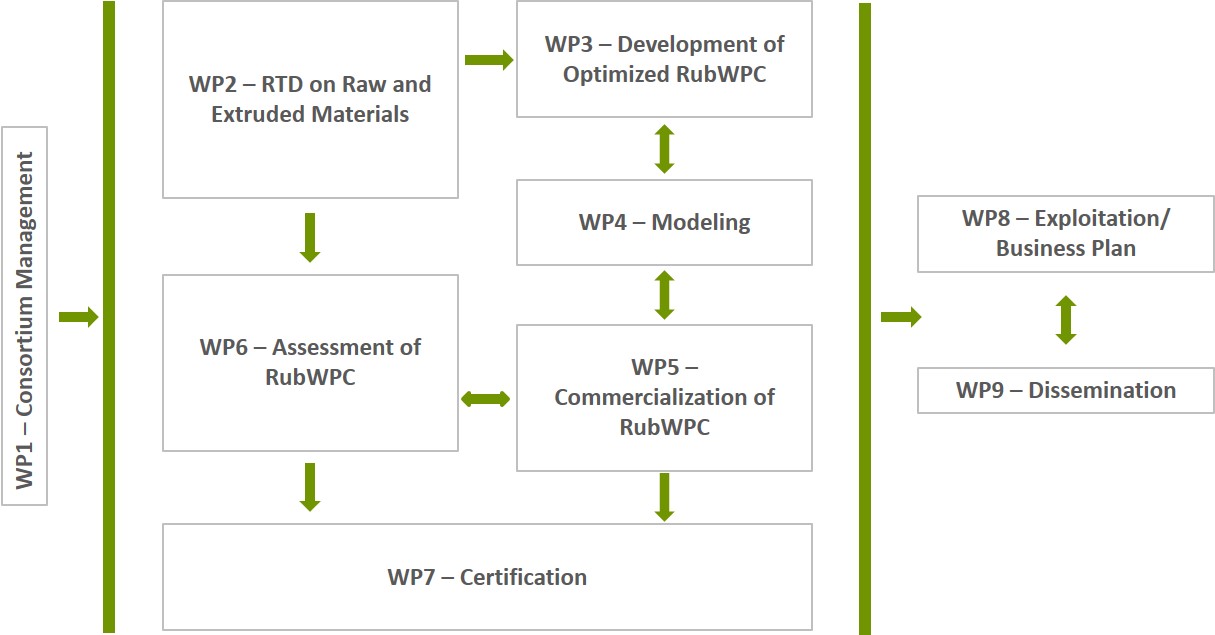

Work Programme description

The RubWPC programme will accommodate continuing development and refinement of the preparatory research work within Ecodek and Brunel in last two years on the extrusion of rubber wood composites out of 100% recycled materials. The materials used will consist of used tyre rubber, recycled wood and thermoplastic acting as matrix and binder. RubWPC will benefit from inclusion of recycled rubber with the improved wearing, grip, thermal and acoustic characteristics along environmental benefits. The formulation will focus on the compatibility and enhancement of interfaces among rubber and plastic and wood in addition to the thermoplastic encapsulation of wood particles as classic WPC. Commercialisation of RubWPC will be achieved by adjusting the processing parameters of major extrusion procedure (e.g. extruder, flow) and introducing additional minor procedures (e.g. material feed) to the existing classic WPC production line. The RubWPC will be certified for ready replication and market application of the developed RubWPC. Comprehensive database will be established, including mechanical and physical performance, environmental impact and LCA of the developed RubWPC.